Description

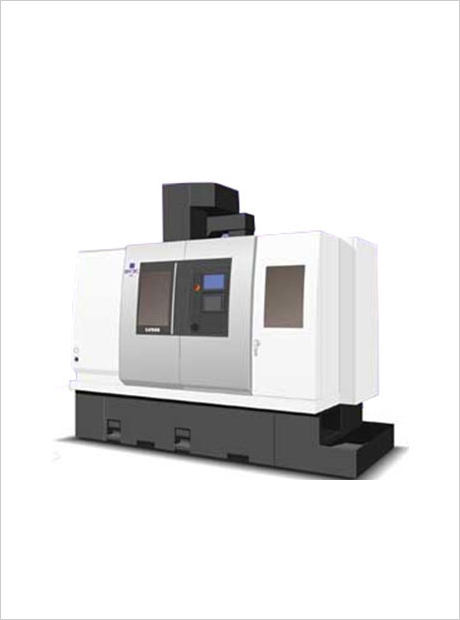

1 spindle and chuck using inverted design, make the workpiece clamping and machining automatically. With the boring conveying mechanism and a turnover mechanism of workpiece, the workpiece can be a feeding, the survival.

2 big torque motor built-in spindle motor, to provide broadband and infinitely variable speed, variable speed range of 30rpm~400rpm.

3 Tibetan oil cooling system uses, decreases the high temperature, to ensure the long time processing accuracy.

The 4 is equipped with a workpiece overturning mechanism, realize the workpiece turnover action, convenient to complete the double-sided machining quantity.

The 5 chuck inverted clamping work, avoid to scratch the workpiece, effectively improves the chip of horizontal machining center is not good, to ensure the accuracy of.

6.12 station feeding, ensure the machining efficiency.

7 rotary knife tower cutter provided with 12 VDI rotary tool position, allows arbitrary X to Z tool, to installation, which are used for milling, drilling, tapping.

8 has the function of C axis, C axis resolution is 0.001 degrees.

Focus Us

Focus Us